Around the world, hundreds of thousands of people are waiting for lung transplants. Indeed, lung disease is the third most common cause of death globally. Not only that, but millions more people need short-term artificial lung devices due to emphysema, COPD, acute respiratory distress syndrome (ARDS), Covid or other conditions.

While artificial lung technology exists, it has shortcomings associated with the internal gas exchange membrane of the device – it simply doesn’t work as effectively as healthy human lungs and poor blood flow can lead to clots. Furthermore, it can’t be used for long periods of time while people wait for lung transplants.

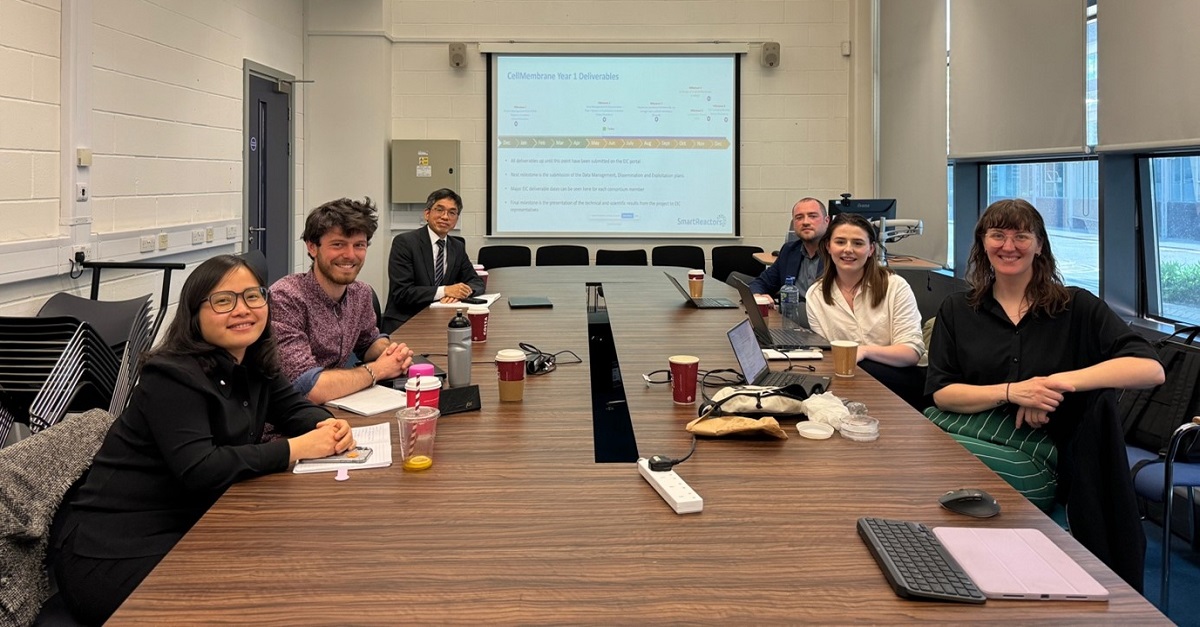

CellMembrane, a European research project led by Irish medtech firm Smart Reactors, is developing a nanocellulose membrane that could transform the fortunes of those with lung disease around the world.

“We’re taking woody plant matter, effectively like sawdust, processing it at a nanoscale level and building a scaffold that will act as an artificial lung,” explains Mark Brassil, Smart Reactor’s co-founder and Chief Technology Officer.

True innovation in organ technology

This 3D printed membrane, made from biomaterials, is sustainable and relatively low cost. It’s highly biocompatible and mimics the gas exchange processes in human lungs.

“What we’re doing is radically different and novel to the current way of manufacturing these devices. As it utilises 3D printing technology, it is significantly more cost-effective to manufacture,” says Brian Haddigan, co-founder and Chief Executive Officer at Smart Reactors.

What would all that mean for patients? Far fewer blood clots and the ability for people to use artificial lung technology comfortably for much longer – bridging the time it takes for them to get a lung transplant.

Not only that, the vision in Smart Reactors is that the underlying bio-based scaffold technology can be used to grow cells and develop replacement tissues for other organs like the kidney or liver.

“What we’re looking to do is create a structure and grow cells on that structure,” says Mark. “We’re growing lung cells, because we want gas exchange, but theoretically, you could grow kidney cells or liver cells. That means you could replace other organs with the same scaffold technology.”

European partners funded by EIC (European Innovation Council) Pathfinder

CellMembrane was funded by the EU’s Horizon Europe programme to the tune of €2.5m, €1.14m of which went to Smart Reactors (the project lead) and the other Irish partner, the University of Galway. The other project partners are Brunel University London, the University of Tübingen and 3D bioprinting specialists Cellink, which is part of global bioscience company Bico.

Six months in, Brian says the collaborative partnership approach is working well. “As the lead partner, we manage the collaboration milestones, he explains. It can be challenging at times to set the tone and get everyone working together with a common goal, but it’s going well.”

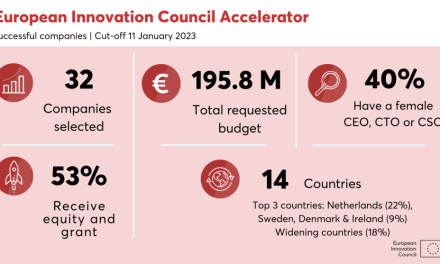

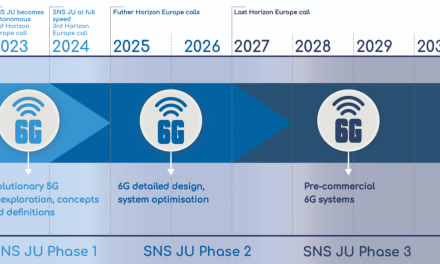

Specifically, the Horizon Europe funding is coming from the Pathfinder funding programme run by the European Innovation Council (EIC). This is, the EIC explains, designed to fund the progress of “breakthrough deep tech projects with a high degree of scientific and technological ambition and risk”.

In supporting such early-stage, high-risk research, Pathfinder differs from other EIC and Horizon funding programmes, says Brian.

“This programme marries academic research with industrial research much earlier. These are projects that break new ground and do something that is not done before. The path isn’t proven – we have to prove it. There is a lot of brainstorming and discussion between the collaborators in four countries on how to get going.”

The long journey to regulation

The initial funded stage of the CellMembrane project is expected to take three years, at the end of which the project partners should have a working prototype that meets clinical needs.

“That prototype will meet clinical needs, meaning it will work in blood and will do the gas exchange like lungs would do,” explains Mark.

The journey will continue through extensive development to get the product to the point where it will succeed in securing regulatory approval, but that stage is a more well-trodden path, says Brian.

“What we’re doing in these early years is looking for some positive signal we can make a difference.

The pathway for later stage device development, clinical evaluation and commercialisation is proven. It’s work, it’s time and money, and it’s direction, but the highest risk is in early research.”

Smart Reactors have had success in a short period of time with its high-performance Camouflage™ coating technology, used to enhance the long-term performance of blood-contacting devices. Brian and Mark were able to draw on this innovation and experience to develop CellMembrane. They also hope to use their proprietary Camouflage™ coating on the membrane they’re developing.

Blue sky thinking needed for true innovation

For other researchers interested in pursuing Pathfinder funding, Brian’s advice is to think big, even to think huge. “Your research has to be groundbreaking,” he says.

“It’s not about trying to make it fit into an existing programme. You have to come up with a blue-sky idea that is very different to anything else that’s out there. It’s not a quick funding application, but something that requires a lot of thought and connection with international collaborators who could add value.”

For information or advice about accessing Horizon Europe support, please contact HorizonSupport@enterprise-ireland.com or visit HorizonEurope.ie.